Aluminum Welding in Westfield, Indiana

-

Preparation

If you know welding, then you know, one of the more complicated types of materials to work with is aluminum. The most important aspect of welding with aluminum is the preparation of the metal. Aluminum oxidizes very quickly and can cause issues with your weld; which is why keeping your base metal clean is crucial. Using a metal brush is not enough, you must use a degreasing solvent to prevent impurities.

-

Technique

Aluminum is non-corrosive, lightweight, and pleasing to the eye, making it an ideal choice of material for a wide variety of welds. However, the same traits that make aluminum desirable can also make it tricky to work with. It is soft, highly sensitive, and is insulated by a tough oxidized layer, it has a higher thermal conductivity and low melting point, it has a smaller window of workability than other metals and can easily lead to burn through.

-

Safety

Safety is another critical component to welding aluminum or any material for that matter. Always ensure you wear the proper protective equipment such as goggles, safety glasses, a welding helmet with the appropriate lens shade number, gloves, and protection necessary to avoid burns.

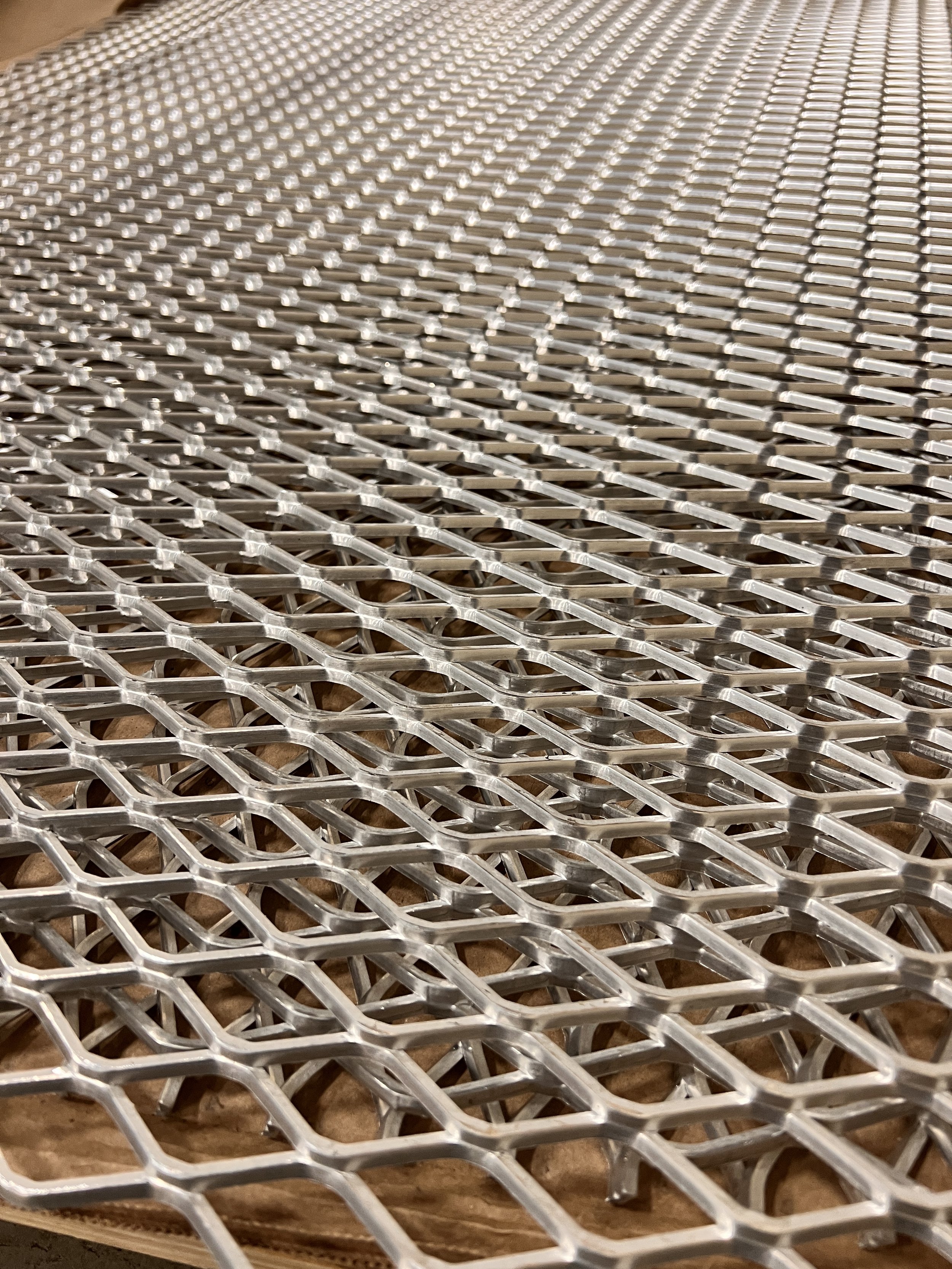

G&G’s Aluminum Projects

When G&G was founded, 100% of our fabrication was with Carbon Steel. As we continue to grow, we continue to learn different welding techniques that have opened the doors for Aluminum fabrication. What kind of aluminum welding or fabrication needs do you have? How can we help you? We are ready for your aluminum project!